Extremely fox: use the most "rigid" body to escort the safest travel.

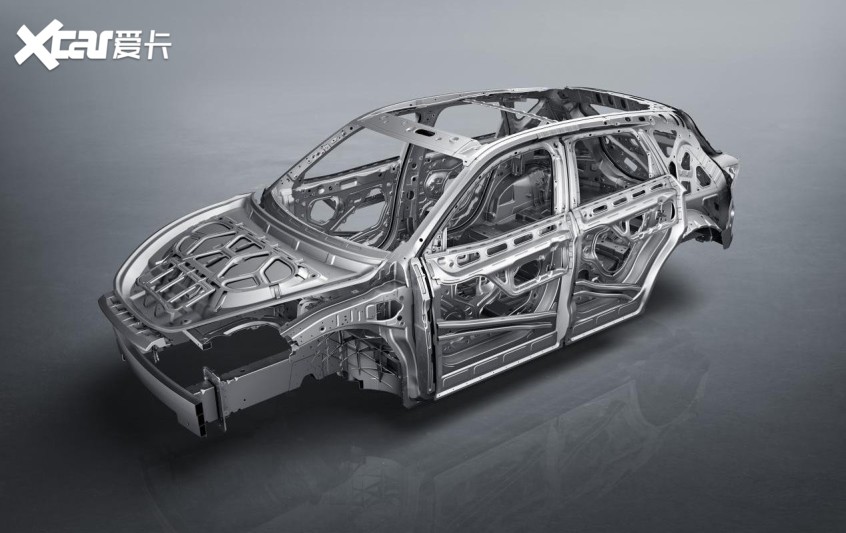

The sense of security brought by "steel bars and iron bones" is irreplaceable, and this last barrier is passive safety. Under the background that major automobile brands are committed to improving the level of passive safety, Extreme Fox has shown its "hard work". During the 2021 Chengdu Auto Show, a body-in-white appeared on the same stage with heavy models such as Extreme Fox Alpha T, Extreme Fox Alpha S and Alpha S Huawei HI Edition, which attracted a lot of attention.

Hard "rigid" body, creating a safety firewall to ensure worry-free driving.

Since the birth of the world’s first car in 1886, the body materials have been evolving all the time. At present, the mainstream body materials of the models on the market include all-steel body, all-aluminum body and steel-aluminum mixed body. With the balanced strength, toughness and plasticity of steel, all-steel car body has become the most widely used car body material, with mature technology and relatively low production cost, but its disadvantage is too heavy; All-aluminum car body has low weight, but it has high cost, complex technology, low strength and difficult maintenance.

With the development of technology, the steel-aluminum hybrid car body came into being. Through the reasonable application and distribution of materials, the steel-aluminum hybrid body combines the advantages of all-steel and all-aluminum bodies. The extreme fox Alpha S and extreme fox Alpha T adopt the steel-aluminum hybrid body with "upper steel and lower aluminum".

In the vehicle structure, the A-pillar and B-pillar are the "firewall" of the driver and passenger, and once deformed, they will occupy the living space of the people inside the vehicle, so it is necessary to use high-strength materials to ensure that they are not deformed. The upper car bodies of Extreme Fox Alpha S and Extreme Fox Alpha T are made of steel with different strengths, thus achieving high-strength collision safety performance while reducing the volume. Especially, ultra-high-strength thermoformed steel beams with the strength of 1500MPa are applied in the positions of A and B pillars and doorsill, which means that it can bear 15 tons of pressure per square centimeter without deformation, ensuring the integrity of the passenger compartment during the collision, thus ensuring the life safety of all drivers and passengers.

If the function of the upper car body is to "resist", then the focus of the lower car body is to "absorb". The lower car bodies of Extreme Fox Alpha S and Extreme Fox Alpha T are made of aluminum alloy, and high-strength aluminum profiles, high-pressure aluminum castings and high-grade aluminum alloy plates are widely used in the covering parts and chassis of the car bodies, among which the aluminum alloy material ratio of Alpha S is as high as 45.5% of the car body material, which ensures the collision energy absorption and collision force transmission while realizing light weight.

The steel-aluminum hybrid car body has the advantages of both materials, but the characteristics of aluminum alloy materials and steel materials are different, so it is difficult to connect them by traditional welding technology. In order to solve this problem, the Blue Valley Magna Factory of Polar Fox applied advanced joining technologies such as SPR (self-piercing riveting process), FDS (hot melt self-tapping screwing process) and adhesive bonding. Taking Polar Fox Alpha S as an example, 1276 SPR locking riveting screws, 430 FDS flow drilling screws and more than 150 meters of high-strength structural adhesive were applied to its car body, realizing the perfect connection of steel and aluminum materials.

Material structure blessing, collapse, energy absorption and buffering, not afraid of external impact.

The "hardness" of the car body can protect the driving safety, and the energy absorption area of the chassis absorbs the impact energy through collapse. Extremely Fox Alpha S and Extremely Fox Alpha T have applied newly developed aluminum alloy profiles with high collapse performance in the transverse and longitudinal beams of the car body, and their performance parameters far exceed the national standard. With the "mesh" structure, the impact energy absorption effect is better; At the same time, the bottoms of the two cars are made of aluminum alloy by secondary vacuum and high pressure casting, which, together with the A and B columns, form a cage-type body structure that is hard enough to better absorb the impact force and prevent structural deformation, and protect the safety of drivers and passengers in the car.

According to the position of the front longitudinal beam, polar fox developed a new aluminum alloy material with higher yield strength and collision collapse bending angle of more than 110 for the first time, which far exceeded the requirements of the national standard and met the requirements of folding and energy absorption of the front longitudinal beam during the collision of the car body. At the position of the front sub-frame, the polar fox has added the collision energy-absorbing structure design, and the full-frame structure of the front sub-frame cooperates with the collapse guide groove structures on the longitudinal and transverse beams, so that the front sub-frame can participate in absorbing the collision energy when the vehicle collides, thus reducing the intrusion injury caused by most accidents at the front of the vehicle.

In order to achieve high strength and excellent crash-collapse performance in energy-absorbing areas of aluminum alloy longitudinal beams, doorsills and other body structures, polar fox engineers adjusted the material parameters of extruded parts, innovated and developed exclusive materials and heat treatment processes for extruded aluminum alloys, and developed materials with crash-collapse bending angles of 120 for different positions, which had better energy-absorbing effect.

Based on China’s C-NCAP and Europe’s E-NCAP, on the side of the car body, the innovative concept of threshold load-sharing beam is applied to the extremely fox car, and the design of combining steel threshold with aluminum extrusion profile is adopted. After the side column collision, the safety distance of the battery is 3.7, which is much higher than the national standard ≥ 0, reaching the leading level in the industry, and ensuring the safety of personnel after side collision in the actual driving process.

Hard-core battery protection, external impact resistance, internal leakage fire prevention

When a car collides, it will not only have a fatal impact on people, but also squeeze the battery to explode, causing secondary injuries. Therefore, while doing a good job in occupant protection, we should also do our homework in battery protection.

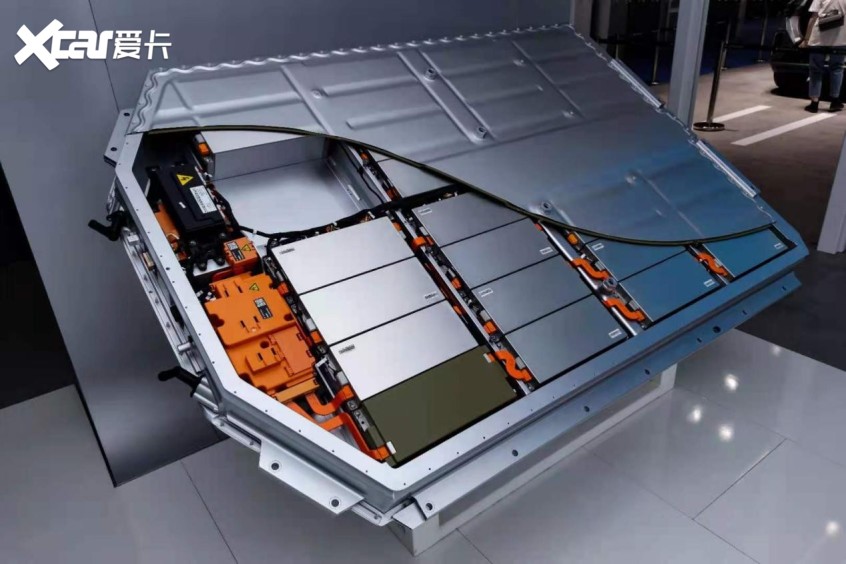

As a product based on the pure electric architecture of forward development, Polar Fox integrates the overall design of power battery into the design and development of car body and chassis. Through 26 connection points, the power battery is closely connected with the whole car to ensure the overall rigidity of the car body. At the same time, through the design concepts of deformable zone, buffer zone, weak deformable zone and non-deformable zone (the battery is non-deformable zone), the whole vehicle is guaranteed to absorb most of the energy during collision and protect the safety of the battery; The lower box of the battery pack adopts "keel" frame aluminum alloy profile, which provides enough bending and torsion resistance for the battery pack and ensures the rigidity of the battery (the bending rigidity is 5132 nm/degree, and the requirement is > 3000 nm/degree).

External impact resistance, internal leakage and fire prevention, the high-voltage copper bar of the battery electrical system of Polar Fox adopts the concept of middle channel layout, which can avoid side collision and short circuit, and the high-voltage circuit of the battery is equipped with main fuse, which can realize millisecond fuse protection in the case of external short circuit of the whole vehicle; The high-voltage wiring harness is designed reasonably and arranged in the middle to reduce the possibility of damage and leakage after collision; The battery pack is designed to meet the double standards of national standard and European standard, and is internally equipped with fire-proof structure, which can strive for sufficient escape time in extreme cases (such as accidental collision) and fully protect the personal safety of drivers and passengers. In addition, polar fox pioneered the design of liquid cooling system with dry-wet separation in the industry, which ensures that the coolant will not enter the high-pressure area in the case of damage to the coolant system. It is worth noting that, while having the technical advantages of fire prevention and collision safety, the battery pack of Polar Fox meets the technical standards of IP68 and IP69K for dust prevention and water discharge, and can prevent high-pressure water spraying.

In more than 1,000 hours of simulation test and more than 100 rounds of actual test under more than 20 collision conditions, the power battery of Polar Fox was not damaged. In the column impact test, the polar fox got a perfect score of 16, and the battery pack achieved zero damage. In addition, the polar fox has reached the level of excellent C-IASI and five-star C-NCAP.

Safety is a compulsory course for automobiles, and all products of Extreme Fox are developed based on IMC platform architecture. This platform architecture, which is newly built by Magna International Team, applies a lot of excellent design and advanced concepts, and adopts different materials and manufacturing processes according to different regional characteristics in body design, which is suitable for materials and achieves a balance between weight and performance. It is such a hard-core background that we have the "hard work" of the safety of the polar fox, thus creating a demonstration model of "vehicle safety and battery safety" and becoming what new energy vehicles should look like in people’s eyes!