It is my life’s mission to crack the rumor of "Long Mai" at Yan ‘an Interchange and build a bridge.

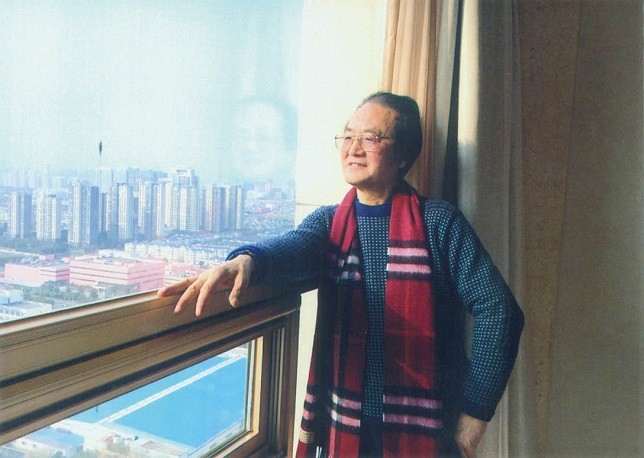

Brief introduction of Zhang Geng: Born in 1943. He used to be the captain of the 101 construction team of Shanghai No.1 Municipal Engineering Company, the manager of the first branch of Shanghai No.1 Municipal Engineering Company and the general party branch secretary, and the chairman and party secretary of Shanghai Rang Municipal Engineering Company. He was awarded the title of hero of major engineering construction in Shanghai for 11 times, the title of model worker in Shanghai for four times, and the title of Top Ten Pioneers in Shanghai, National Model Worker, National Top Ten Moral Model and National May Day Labor Medal. Representative of Shanghai Municipal People’s Congress and the 15th National Congress of the Communist Party of China. The municipal 101 construction team led by him won the title of Bridge-building Heroes and the National May 1st Labor Medal.

Dictation | Zhang Geng finishing | Sun Hongkang

I was born in poverty. When I was a child, my parents kept telling me to be grateful. I am grateful for our times, and it is the reform and opening up that has given me a bigger platform to display my skills.

The hard experience of the fiery red age

I was born in Shanghai in 1943. According to my father, my ancestors were poor farmers near Zaozhuang. In the early years, my great-grandfather fled to Jiangning rural area outside Nanjing with his family. Later, my grandfather went to married with children to work and earn a living. At that time, my father was only 9 years old.

Living in this poor family, I am also a sensible child. I watched my father go to work in such a distant unit to support his family, and my mother had to manage the affairs of this large family and get busy with her work. As the eldest son, I had the idea of sharing responsibility in my heart. At that time, Shanghai Railway Bureau was implementing the construction project of Shanghai-Nanjing double track, and it was urgent to set up a construction team of tens of thousands of people. As a result, I just turned 16 and became a construction team member. Every day, I devoted myself to the iron flow of Shanghai-Nanjing double-track construction. After a year, the double-track project was completed, and I was honored as an "excellent team member".

After the Shanghai-Nanjing double-track project, I reported back to the street. Soon, the street recommended me as an "excellent member" of the railway front to work in Shanghai Steel No.3 Plant. It was the end of 1959, and I became a steel worker. Shanghai Steel No.3 Factory is located in Zhoujiadu, Pudong. I work in the steel casting workshop. The heat is scorching, and my clothes are soaked again and again every day. I’m a rigger in the steel casting workshop. After steelmaking, I have to use a crane to lift and haul away the remaining slag bags. I got used to the smell of sulfur and asphalt accompanying steelmaking. I suffered hardships, endured tiredness, sweated and performed well, and was rated as the production model of Shanghai Steel No.3 Plant every year.

In 1962, a number of key projects were dismounted, and the economic front contracted, which also brought trouble to our steel mills. By February 1963, I reported back to the street. Less than a month later, the street introduced me to work in the municipal engineering team. I finally found a job that I can entrust for life. Looking back now, the positions I have experienced and the jobs I have engaged in seem to be preparing for this job that suits me best.

I joined the 101st Engineering Team of the First Engineering Brigade of Shanghai Municipal Corporation on March 5th, 1963. At that time, I was young, quick-witted, in good health, full of energy, and had many years of experience as a worker. Considering that I worked as a rigger in a steel plant, the company arranged for me to work in the lifting team of the 101 engineering team. This type of work gives full play to my specialty and makes me work like a duck to water. There are nearly 20 workers in the lifting team, among them, several old wizards are level 6 or level 7 workers with rich experience and high level. I humbly learn from my teacher and study hard.

I made rapid progress in the lifting team. In 1965, I was appointed as the captain of the lifting team. I brought our team together with my sincerity.

Construction team leader who takes the construction site as his home.

Municipal construction means building bridges and roads; Building bridges and roads is to benefit the people. Some people think that building roads and bridges is an open-air job, which is too bitter because of the sun, rain, wind and frost. I don’t feel bitter. I like this job from the bottom of my heart. I have decided that this job is suitable for me and it is my "golden rice bowl". I will hold it tightly.

From then on, I put my mind into my work and spilled my sweat on the construction site. In 1965, I was named "Five Good Workers" in Shanghai. In 1971, I joined the Party at the Suzhou Creek Bridge Construction Site. When I raised my right fist in front of party flag to take the oath, I sincerely felt that my shoulders were heavier. That was the sense of responsibility of Communist party member.

In 1975, the municipal company appointed me as the captain of the 101 construction team. From the date of this appointment, I moved the bedroll to the construction site and regarded the construction site as my residence. Since then, all the year round, from morning till night, I have been eating at the construction site, working at the construction site, sleeping at the construction site, and even lying on the construction site when I am sick. Anyway, where the project is, the construction site is. Or camp along the river, or set up a tent in the wild, or set up a tent everywhere, spread a straw mat on the ground, and put the bedding on the floor. In a word, it’s common in cold and hot weather, rain and snow, and let it go when mosquitoes bite.

I remember that the project of Suzhou Creek Hengfeng Road and Bridge was complicated. At that time, our construction equipment was old and the construction period was long. During the construction period, I didn’t go home once for five months. I remember the Suzhou Creek Cao Yang Road and Bridge Project, which was more difficult to construct because of the busy water transportation in the bend and the complicated land traffic. At that time, my home was in Jinsha New Village, Cao Yang Road, only 10 minutes away from the construction site, but my mind was focused on the bridge-building project. The Suzhou River ebbed and flowed every day, and the construction conditions were different. Construction problems would pop up at any time. I didn’t dare to be careless at all, and I didn’t dare to leave the construction site for a minute.

The Wusong Bridge project, which is related to the construction and development of Baosteel and affects the travel and life of Baoshan people, was originally scheduled to last for three years. However, after our construction team undertook this 968.7-meter-long bridge project, it took only 19 months to build it with high quality by going all out, innovating processes and overcoming various problems.

One day, during the construction of the No.10 pier of Wusong Bridge, serious seepage suddenly occurred, and the foundation pit of the pier with a depth of 5 meters was leaking, which was very critical. I led the construction team to drain water while building dams. After three days and three nights of continuous rescue, I finally eliminated the danger and saved the foundation pit. We have been immersed in the river for so long that we can’t move any further.

After serving as the construction team leader, I not only don’t live at home at ordinary times, I don’t eat at home, and even I can’t guarantee to eat at home for the New Year’s Eve. I remember that during the construction of major projects such as Songpu Bridge, Jinshan Bridge, Hujia Expressway, Wusong Bridge, Taipu River Bridge, nanpu bridge, Hengfeng Road Bridge, North-South Elevated Bridge, etc., in order to ensure the quality and the construction period, during the construction period, I can’t go home to reunite with my family every New Year’s Eve, stay at the construction site for the new year’s eve, and have dinner with my workers during the construction.

Tempering the "Bridge-building Heroes" in the Storm

In our municipal construction front, bridge building is a job with the greatest technical difficulty, labor intensity and construction risk.

Bridges are different: there are bridges on the river, bridges on the river, bridges on the lake, bridges on the bay, dry bridges on the railway and elevated roads. Bridges on rivers are the same. The rivers are wide and narrow, and the bending potential of the coastline is not the same. Moreover, the geological conditions and soil characteristics of each bridge are different, and the traffic conditions and transportation vehicles carried by each bridge are different. The situation of bridge construction in urban areas and rural areas is even different. Our construction plan, construction equipment, construction period and construction progress will be handled flexibly according to the situation.

Suzhou Creek is the mother river of Shanghai, and the construction team led by me, as the main team of bridge construction in Shanghai, has been dealing with Suzhou Creek for decades. In the process of exploring the law of bridge building, I am more and more familiar with the temperament characteristics of Suzhou River. For example, when we build the Suzhou Creek Bridge Project, we will avoid the high tide every day. The Suzhou River ebbs and flows twice a day, which is roughly the same as other rivers. However, the ebb time of Suzhou River is different every day, and its ebb time will be 45 minutes every other day. We know its temper thoroughly, and we can always accurately "you retreat and I advance" to race against time and improve work efficiency.

In the summer of 1986, Kangqu Bridge Project, a practical project of Zhongshan Nanyi Road, which is matched with Luban Road Cross-river Tunnel in Huangpu River, entered a tense construction stage. This project has a complicated construction environment and high design requirements. Besides, "Kangqu Bridge" seems to be a bridge. In fact, there are seven bridges to be built in this bid section. In order to make the Luban Road cross-river tunnel open to traffic on schedule and benefit the citizens, the municipal government has given a dead order to the "Kangqu Bridge" project, and must win this arduous project within five months.

I know this is a tough battle, and I can’t be vague. I jump on the construction site every day, keep an eye on every link, overcome all the problems, and compress my sleep time to about 4 hours every day. During this time, due to overwork and little sleep, periodontitis broke out, my cheeks were red and swollen, and half of my face was painful. However, "toothache is not a disease, but the project is the most important", and the Kangqu Bridge project was completed on December 23 of that year.

The Zhenbei Road overpass we built left an unforgettable impression on me. This overpass connects Shanghai-Nanjing Expressway and Wuning Road, and is known as the majestic west gate of Shanghai. The investment of this bridge is 500 million yuan, accounting for a quarter of the total investment of Shanghai-Nanjing Expressway. It is the largest bridge undertaken by our municipal construction team since its establishment.

On Zhenbei Road overpass site, we have laid nearly 3,000 concrete piles, dug out 200,000 cubic meters of soil, erected more than 2,000 beams, poured 380 meters of concrete box beams, poured 14 kilometers of concrete for scour walls, buried 12 kilometers of rainwater pipes and sewage pipes, and paved 79,000 square meters of bridge pavement and 89,000 square meters of asphalt ground roads. My team and I have created a miracle of completing this grand project with high quality in 600 working days.

Zhenbei Road Interchange Project is the pride of our team and a monument to the history of Shanghai’s municipal construction.

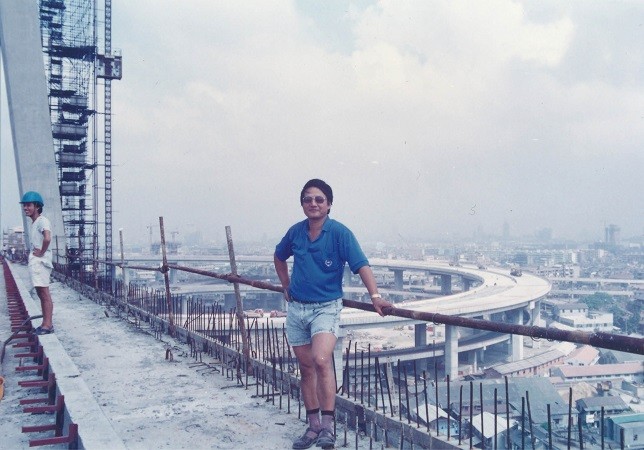

I am 76 years old this year. In retrospect, I have participated in the construction of nearly 90 bridges in my life. I have devoted my hard work and wisdom to the cause of bridge building. At the beginning of 1994, the leading group of Shanghai key project practical competition named the municipal 101 construction team I led as "Bridge-building Heroes Team".

Deep debt to family.

For decades, I have been focusing on engineering and taking the construction site as my home. Naturally, I care very little about my family. My wife, Tang Hongmei, worries about big and small things at home.

I got married on December 31st, 1968. On the third day after my marriage, I packed my bags and went to Minhang construction site.

Since the 1970s, one task after another, and then catch up with the development opportunities of Shanghai in three years, our municipal engineering company has undertaken more and more projects.

For decades, I lived and ate on the construction site. My wife has adapted to me not going home for a month, two months or even three months, and she will be very surprised when I suddenly go home every two weeks.

My wife is very understanding and supportive of my work. My wife only complained about me once. That was in 1988. My daughter Xiaojun was ill and had a high fever. She didn’t have a fever for seven days. My wife was so anxious that she called me at the construction site in the telephone room. I got the call at about 6 o’clock in the evening, but unfortunately, there were a lot of difficult things on the construction site that day. By the time I got home, it was already more than 9 o’clock in the evening. That night, fortunately, I hurried home. Near midnight, my daughter not only had a high fever, but also her whole body twitched. I quickly carried my daughter down from the fourth floor, caught the last bus and sent her to the hospital for emergency treatment. My daughter didn’t have a fever until 3 am. My wife muttered, "I owe you to go home tonight. Otherwise, what should I do?"

I take building bridges as my life’s mission, and I have no regrets for paying more for it. However, when three of my relatives died successively, it was because the construction project just entered the critical construction stage. As the on-site commander, I couldn’t leave immediately, so I couldn’t rush to bid farewell. I regret this for life.

My father was honest and worked hard all his life. He moved from Nanjing to Shanghai with my grandfather at the age of 9; In order to earn money to support his family, he went to work in a leather workshop at the age of 10.

When my father reached middle age, he was diagnosed with emphysema, and he coughed badly, especially at night. At the beginning of February, 1990, my father became ill again, and he was very fierce. He was rushed to the hospital for emergency treatment. As a result, he found out that his father had lung cancer, which was advanced. His father was 72 years old that year. Upon learning of this terrible news, I rushed to the hospital from the bridge site in Jinshan County, and hurried into the ward to visit my father lying in the emergency bed. I inquired about the illness and rescue situation in detail, and my sister and brother comforted me. My sister said, "You are busy, you should go first. We have arranged for six brothers and sisters, and we will take good care of my father." Unexpectedly, this trip turned out to be a farewell to my old father.

Only seven days later, my father left us forever. At that time, I was devoting myself to the construction of Zhujing Bridge in Jinshan County. That day, when I received an urgent telegram from my sister reporting that my father was critically ill, our construction team was rushing to build the main pier, so I couldn’t leave the command post immediately. Besides, the road from Jinshan to Shanghai was very narrow at that time, and there were not many long-distance bus flights. When I arrived at the hospital with great anxiety, my father had already died, and the family was waiting for me in the ward with his body. Seeing this, I was so sad that I burst into tears.

Unexpectedly, just one year after my father’s death, my older brother had a heart attack, and my sister called to report the emergency. I was at the site meeting of the finishing project of Jinshan Bridge. As the commander in chief, I was adjusting the plan, assigning tasks, making demands and telling details. At this juncture, I really couldn’t leave immediately. At 7: 30 that night, the family called again, and the emergency call turned into a funeral call. This time it was my wife. She choked on the phone and said, "Don’t come back, your brother has left!"

1993 was a "bumper year" for our major projects in Shanghai, and many projects that benefited the citizens were successfully completed in this year. This year, I fought day and night on the construction site of Wusong Bridge, a major project, because I was too busy building the bridge to bid farewell to my mother, which left me with eternal pain in my heart!

My mother suffered from diabetes in her later years, and her blood sugar index was very high. Later, she gradually couldn’t see clearly, suffered from glaucoma, and finally became sick and complicated, causing several comas. In those years, every time she was hospitalized, I would make time to visit. Of course, my elder sister and younger sister are the main caregivers. In June, 1993, my mother got sick for the last time. At about 3 pm that day, my sister sent an urgent telegram to report the news that my mother was dying. At that time, I was presiding over the emergency meeting of the closure construction of Wusong Bridge. This time, I left the scene as quickly as possible, but I got on the bus and arrived at Putuo District Central Hospital from Wusong. It was nearly 6 o’clock in the evening, and it was late again. My mother had left us forever.

Piling on "Long Mai"

In the early 1990s, in order to meet the needs of Shanghai’s rapid economic development, Shanghai municipal engineering ushered in a construction climax. According to the blueprint of "Three-year Great Change", following the completion of the Inner Ring Road and Yan ‘an Road Elevated Road, the magnificent construction of the North-South Elevated Road has been launched again. This is an important stroke of Shanghai’s "Shen" shaped elevated road running through the north and south.

Naturally, the municipal 101 construction team led by me will not be absent in the construction of the north-south elevated road. At that time, the bid section of our team was the Suzhou River Bridge which was elevated from north to south. This bridge is more than 1000 meters long, and its widest point is 56 meters. In order to ensure the safe and efficient construction in the complex land and water environment, we innovated the technology in this river-crossing project, and all of them adopted the construction of hanging basket without support, which took only 16 months from the start to the completion.

In the construction of the north-south elevated road, our team originally built the Suzhou Creek Bridge, but who would have thought that the well-known battle of piling on the Yan ‘an Road overpass "Long Mai" happened to hit me again!

Yan ‘an Road Overpass, where the north-south viaduct and Yan ‘an Road viaduct meet, was ranked first in Asia at that time with a height of 31 meters. This overpass runs through the east, west, north and south, and the ramp turns left and right, which is divided into five floors. In order to support the multi-storey bridge deck and reduce the number of piers, the designer designed an extra-large cylindrical pier with a diameter of 4.2 meters, which effectively supported the four-storey bridge deck of the whole interchange.

It is this extra-large cylindrical pier, and the story of piling on the "Long Mai" around it in those days can be spread to the gods.

The project of Yan ‘an Road Overpass was undertaken by a large company in this city. They subcontracted the piling project of the main pier to a partner-a foreign construction company. Although this construction company has the professional ability of piling, it used to lay foundation piles for plant construction, and it has never encountered such a "hard bone" with broken teeth.

The company is based in Baosteel, and the construction team members are picked up and dropped off by shuttle bus every day. On the way back and forth, it coincides with the rush hour. It takes nearly two hours for a single trip. At 9: 00 a.m., they arrive at Yan ‘an Road site to start piling, stop piling at 3: 00 p.m. and get back to the station in the evening. This stop-and-go piling method is exactly the taboo of piling.

According to the original design, Yan ‘an Road Overpass will be driven with 6 rows of steel piles, totaling 36 piles, each with a diameter of 90cm and a length of 64m. The company’s piling equipment is a large-tonnage pile hammer imported from abroad, and the piston core weighs 8 tons, which is qualified.

However, there was something wrong with the company’s construction method. The first pile was not driven down, only 46 meters deep, and the remaining 18 meters of piles were exposed to the ground. They drove a total of six piles, the deepest one was the first pile, which went down 46 meters, the shallowest one only went down 26 meters, and the pile exposed to the ground was 38 meters.

In the face of such a big problem, piling had to be suspended, but rumors spread. He said that this is where Long Mai is, and piling piles here caused the Dragon to get angry, but he had no choice but to invite the abbot of the eminent monk to make up for the "ritual". Although red candles were fragrant for days, it still had little effect.

The engineering headquarters believes that rumors must be stopped, superstitions must be broken, and problems must be solved. On that day, the leaders of engineering headquarters and municipal design institute invited me to the construction site for "consultation". I checked the relevant geological data, and learned about the previous piling situation, and pointed out that there was something wrong with the original piling method. This 64m steel pile must be continuously piled, and the situation should be taken advantage of. When piling, water should be continuously injected to reduce the resistance, and all the steel piles should be continuously driven down before stopping for a rest.

After listening to my construction suggestion, the leaders of the headquarters and design institute agreed, but the frustrated company spent three months here only driving six piles, and none of them were driven to the end. They refused to continue to work if the construction plan was to be adjusted. So the engineering headquarters agreed to the company’s withdrawal, and instead asked me to "go out of the mountain", and our bridge-building heroes immediately stationed at the Yan ‘an Road overpass site, and hit 36 64-meter-long steel piles in "Long Mai".

After we entered the site, we didn’t start work immediately. Instead, we first won the support of local street organizations and environmental protection departments to do a good job with the surrounding residents, agreed to our continuous construction day and night, and understood and supported us to complete major municipal projects as soon as possible.

After research, our construction team decided to adopt the piling method of "from shallow to deep". We will not move the pile that has been hit the deepest for the time being, but start to make up the piling from the pile that has been hit slightly shallowly. The piling machine is divided into four grades. When starting, we don’t need a heavy hammer first, but use a low-grade light hammer to test and inject water while hitting, so as to reduce the piling resistance, and gradually get the right temper, and then hit it faster and faster, and hit it more and more.

Within a few days, we felt the pattern and mastered the progress. Generally, we laid a pile every day and drove it for 16 hours in a row. We started at 6 o’clock in the morning and finished at midnight. In this way, workers can catch up with their sleep, the equipment can not be overused, and the surrounding residents can have a quiet environment for 6 hours.

In this way, one pile after another, completely in accordance with the design requirements, hit 64 meters deep, 36 piles formed a strong foundation, produced a great force, firmly supported the magnificent Yan’ an Road overpass, and endured the rumbling of vehicles from south to north.

After the completion of the Yan ‘an Road overpass project, the engineering headquarters simply wrapped a layer of metal skin on the outside of the towering big column pier, and there were protruding Kowloon reliefs on it. These nine golden dragons seemed to tell people the story that Shanghai builders did not believe in rumors, were not afraid of difficulties and opened up new roads.

Reform and innovation is my unremitting pursuit goal.

I became a worker at the age of 16, and I didn’t read much. At first, I only had junior high school education. I know my shortcomings and my soft files. On the one hand, I use my spare time to make up for my shortcomings in cultural study. For example, when I was working in the No.3 Plant of Shanghai Steel, I attended night school and high school for two years. On the other hand, I have been thinking more, asking for advice and learning more in my work practice. In practice, I have learned knowledge by combining problems and learned knowledge to solve difficult problems. Fortunately, practice is my textbook, construction site is my big classroom, and bridge building is my main major.

For decades, on the municipal front and on the bridge-building site, although I have been busy with the wind and rain every day, I have never regarded myself as a "lout" and never worked blindly. Every time I receive an engineering task, I carefully study the engineering drawings and compare the construction schemes repeatedly.

A philosopher said that it is impossible to step into the same stream twice. Similarly, each bridge project we undertake is different. Therefore, our construction team has different methods of implementation every time. In the construction of Hengfeng Road and Bridge, according to the actual situation, we adopted a new technology of "prestressed post-tensioned box continuous beam", which changed the previous practice of "full-house support", but hung a "hanging basket" on the main beam of the bridge and pushed it towards the river center bit by bit. This new process is three to five times more efficient than the old one.

In the construction of Wusong Bridge, a key project, we innovated the technology. On both sides of the river, four hanging baskets were used for opposite construction. Previously, we used computers to accurately calculate the prestress of the bridge, thus ensuring the accuracy of the north-south opposite construction. After that, when the continuous beams hundreds of meters long from north to south are closed, the butt joint height difference is only 4 mm, which is much lower than the international standard of allowable error of 20 mm. Such a high-quality and high-precision closure depends on scientific construction, innovative technology and knowledge.

From 1996 to 1998, I took advantage of my spare time on weekends and evenings to attend the advanced course of Master of Economic Management organized by Shanghai Academy of Social Sciences, and got a certificate with qualified results.

The spirit of the 14th National Congress of the Communist Party of China inspired the enthusiasm of our construction team, encouraged us to be brave in innovation and constantly explore the construction field. During the five years from the 14th Congress to the 15th Congress, the output value of our construction team increased at a rate of 40% every year, and the profit of 10 million yuan was paid to the superior company every year, and the return on assets was about 250%.

In those years, our team not only innovated in the construction technology, but also actively brewed changes in the system reform of the construction team. On November 15th, 1997, with the support of Comrade Huang Ju, the first Shanghai municipal engineering company named after me was established.

According to the relationship between assets and bonds, the company is established on the principle of "invigorating the operating mechanism and making big and high-quality assets", and is controlled by Shanghai Zhengyi Company of Urban Construction Group. Of the registered capital of our company, state-owned assets account for 62.5%, and operators and employees hold 37.5%. I am the chairman.

Reform has brought China’s economic development into the "fast lane", brought profound changes to our society and greatly improved people’s living standards. The reform has also brought a brand-new system, new vitality and great changes to our municipal industry.